Valves for Soft Wash Machines

Orders over $100 may be eligible for Free Shipping. Some restrictions apply.

Orders over $100 may be eligible for Free Shipping. Some restrictions apply.

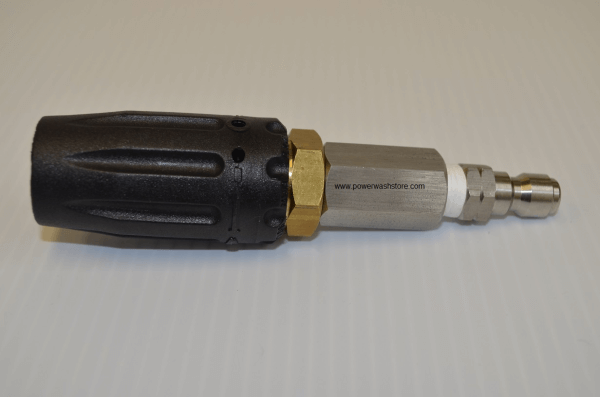

Stock Up on Valves for All Your Soft Wash Applications

At Power Wash Store, we sell durable and chemical-resistant valves designed to bring you precision and control over the flow of your cleaning solution. You’ll never have to worry about your equipment failing you again. We sell high-quality valves to keep your business moving, and we’re happy to guide you in selecting the right valve for your needs.

6 Tips for Choosing the Right Soft Wash Valve

1. Determine which Soft Wash Valve Type and Configuration You Need

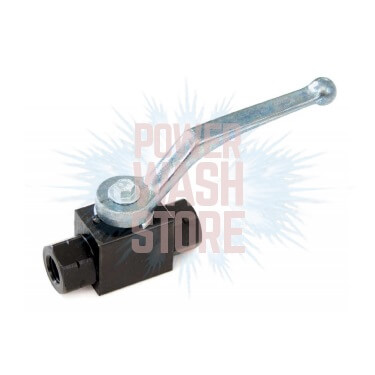

- Ball valves and ball and seat variations for turning the flow on and off

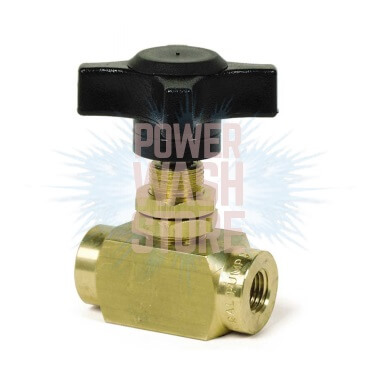

- Gate valves and needle valves to regulate flow

2. Ensure Chemical Compatibility

Make sure the valve material is compatible with the chemicals and solutions you plan to use. Different chemicals require specific valve materials to avoid damage, leaks and corrosion.

3. Check Pressure Rating and Flow Capacity

Opt for valves with a pressure rating and flow rate to match or exceed the operating pressure of your soft wash system.

4. Confirm Valve Operation

Some valves are operated by a lever or handle, while others use a knob or electronic controls.

5. Select the Right Seal Type

Pay attention to the type of seal used in the valve. Soft seats and seals made of materials like EPDM or Viton are often preferred for chemical resistance.

6. Consider Maintenance and Longevity

Look for a valve with user-friendly maintenance features, such as easy-access components and replaceable parts to get a longer life out of your valve.

Valve Quality Matters

Choosing a high-quality valve for your soft wash machine is critical to making sure your machine operates at its prime and doesn’t malfunction or become damaged due to improper pressure or chemical regulation.

Call Power Wash Store to Find Your Ideal Valve

Minimize the risk of leaks or failures, machine damage and wastage and grow your business confidently with a huge selection of valves and unbeatable customer service from Power Wash Store. Call us today to get the best valve for your business.